A daily commitment to working well

From stage to stage, from department to department, our efforts are aimed at maintaining a high quality service and final result through teamwork and attention to detail that distinguish our products.

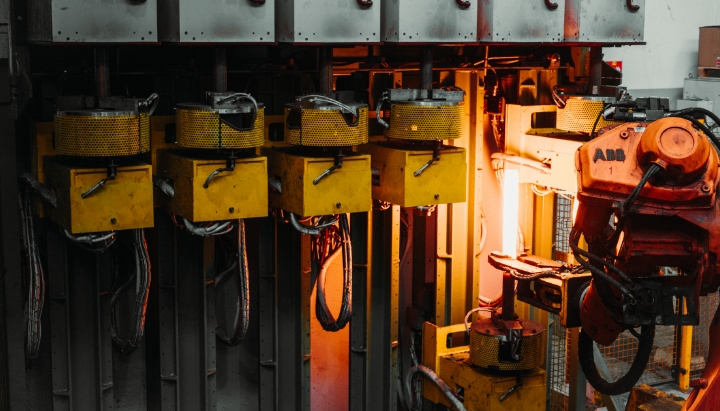

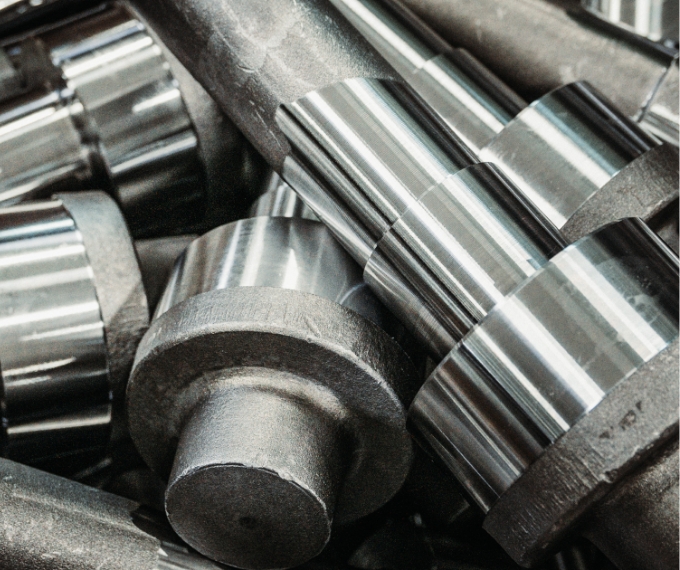

Production process

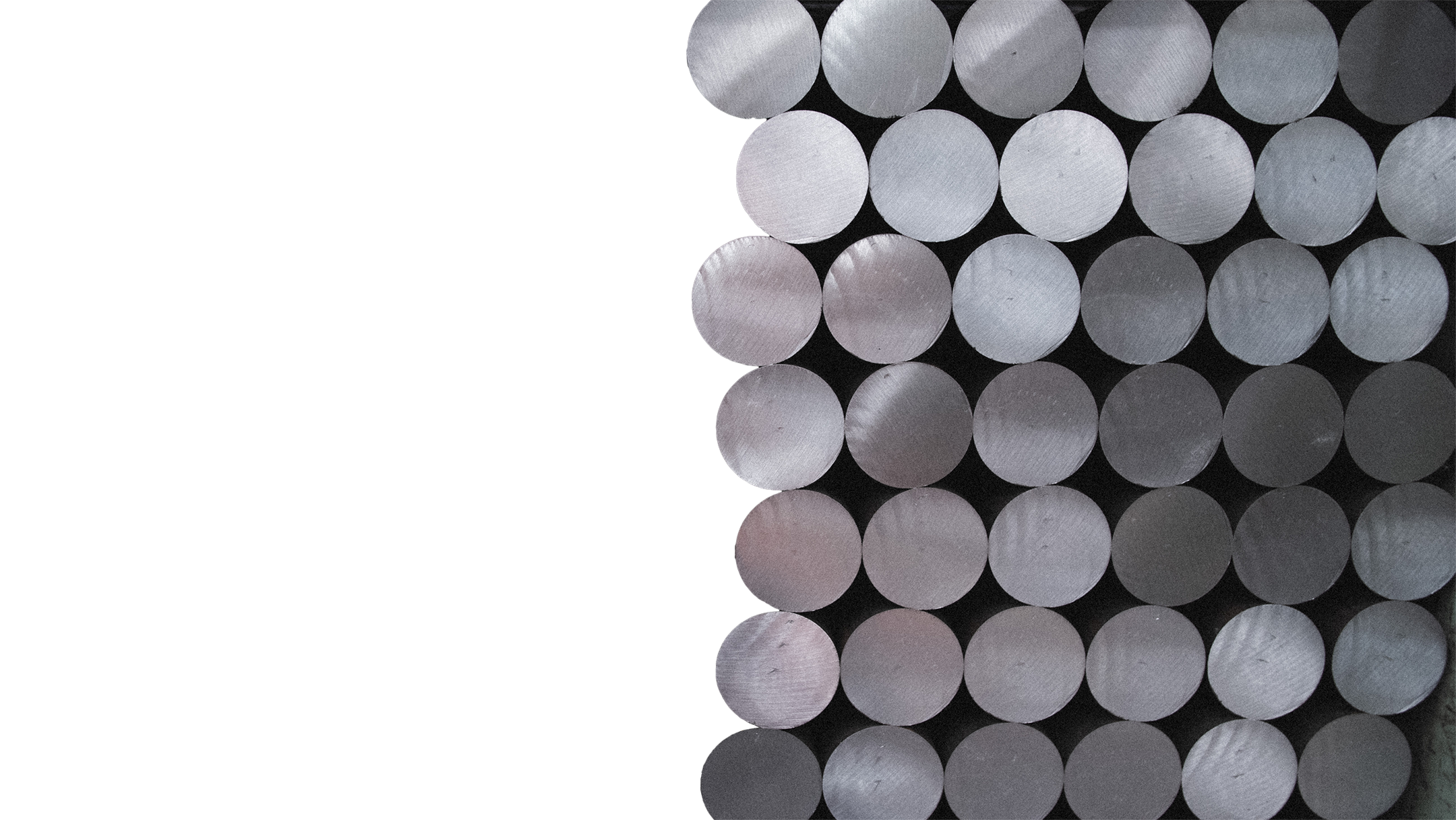

Materials in use

We mainly use raw material from steel mills that guarantee a triple check at the origin declared in the certificate (magnetoscope, ultrasound, antimix).

Each bar is identified by a steel heat identification stamp, guaranteeing total traceability.

Materials used: • Construction steels • Quenching and tempering steels • Case hardening steels • Stainless steels • Duplex and Superduplex steels • Microalloyed steels and other special steels (e.g., Stavax) • Nickel Alloys (UNS N06625, UNS N08825, UNS N04400, UNS N10276, UNS N07718 and others) We can supply steels with special specifications (Caterpillar, Dana, Zf, Shell, John Deere, etc.) depending on the customer’s needs.

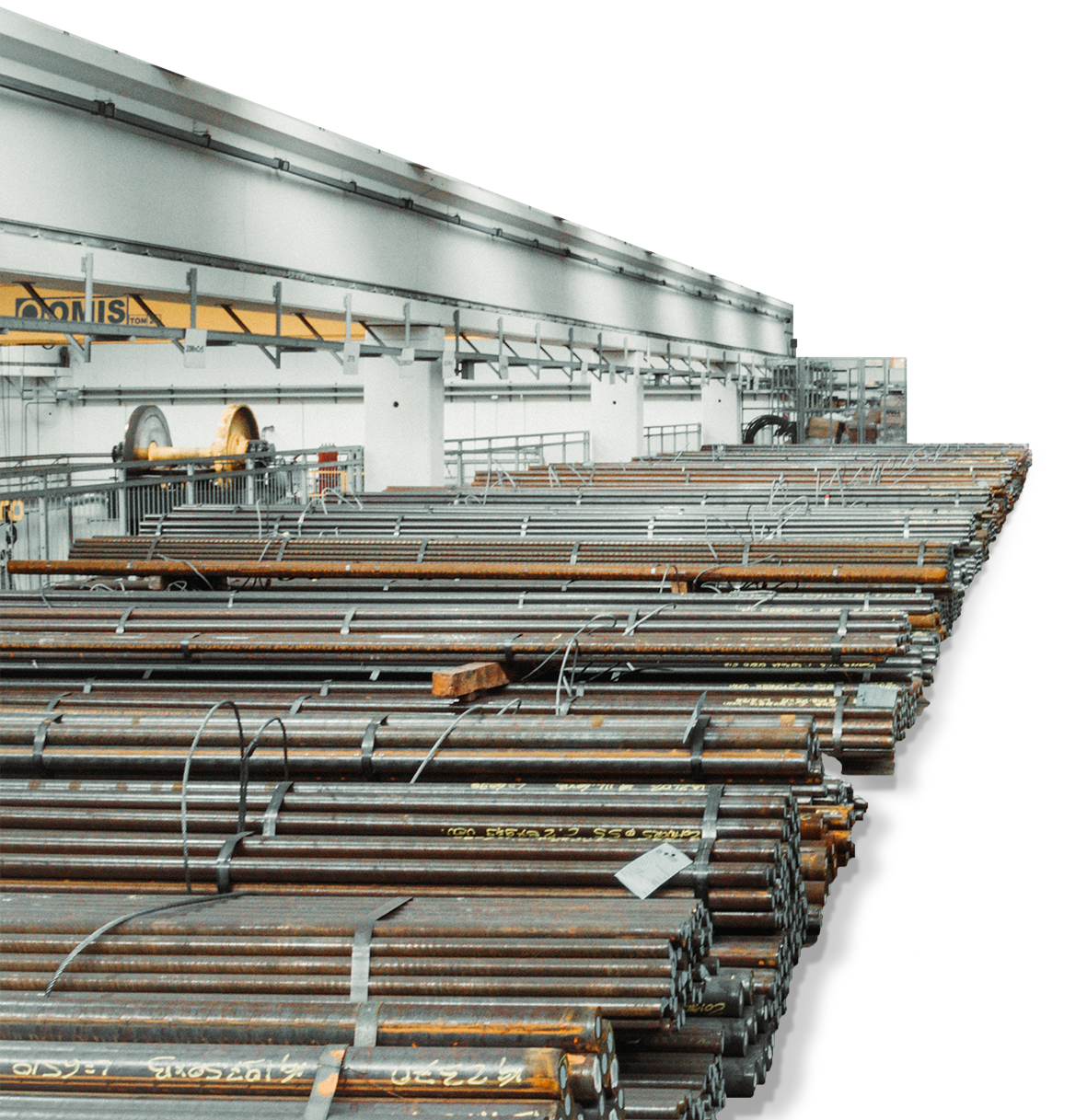

Warehouse

Baldanforge can count on an elevated covered warehouse of about 800 sq. m and an average stock of about 1,500 tons of steel. After being carefully inspected by the staff during acceptance, the bars, differentiated by casting and length, are stored neatly and accurately. The supplier’s traceability stamp certifies their origin and controlled quality.

The in-house location ensures extremely flexible and rapid material handling thanks to the proximity to the production lines.All stages of production are internally performed.

1 - Cutting

2 - Production

3 - Sandblasting

4 - Inspection and final preparation

Our plus

Careful selectionof raw materials

Material markedwith traceability stamps

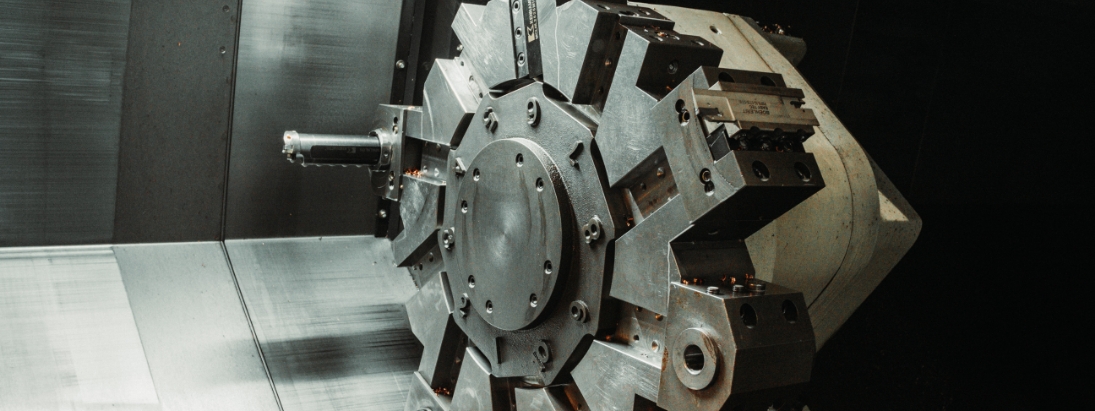

In-house production of moulds

Constant striving to improvement and innovation

Capacious and organisedinternal warehouse

Clean and tidyworking environment

Wide rangeof products

Willingness to listeningand counselling

Dedicated internalmechanical workshop

High technical preparationof the staff

Full attention to reduction of productiontime and material waste

Our plus

Careful selectionof raw materials

Capacious and organisedinternal warehouse

Material markedwith traceability stamps

Clean and tidyworking environment

Dedicated internalmechanical workshop

In-house production of moulds

Wide rangeof products

High technical preparationof the staff

Constant striving to improvement and innovation

Willingness to listeningand counselling

Full attention to reduction of productiontime and material waste