experts in steel

processing

experts in steel

processing

How we workOur passion,

Our passion,

our job,

your satisfaction

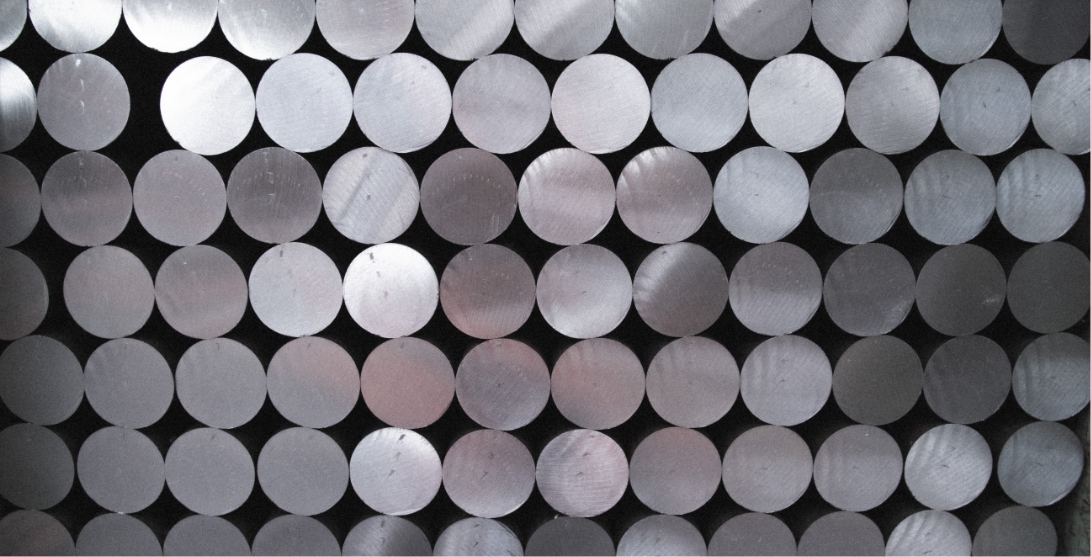

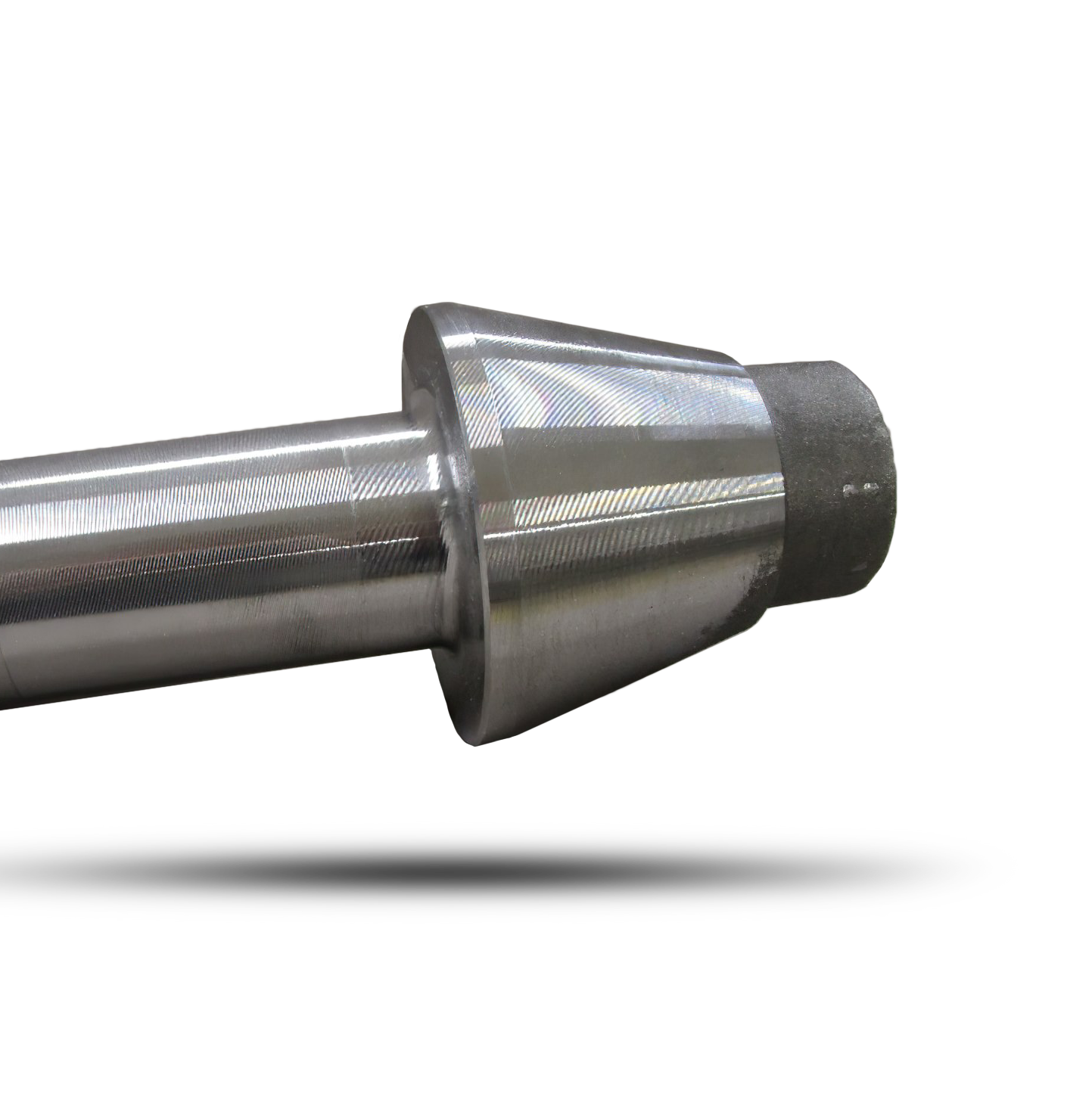

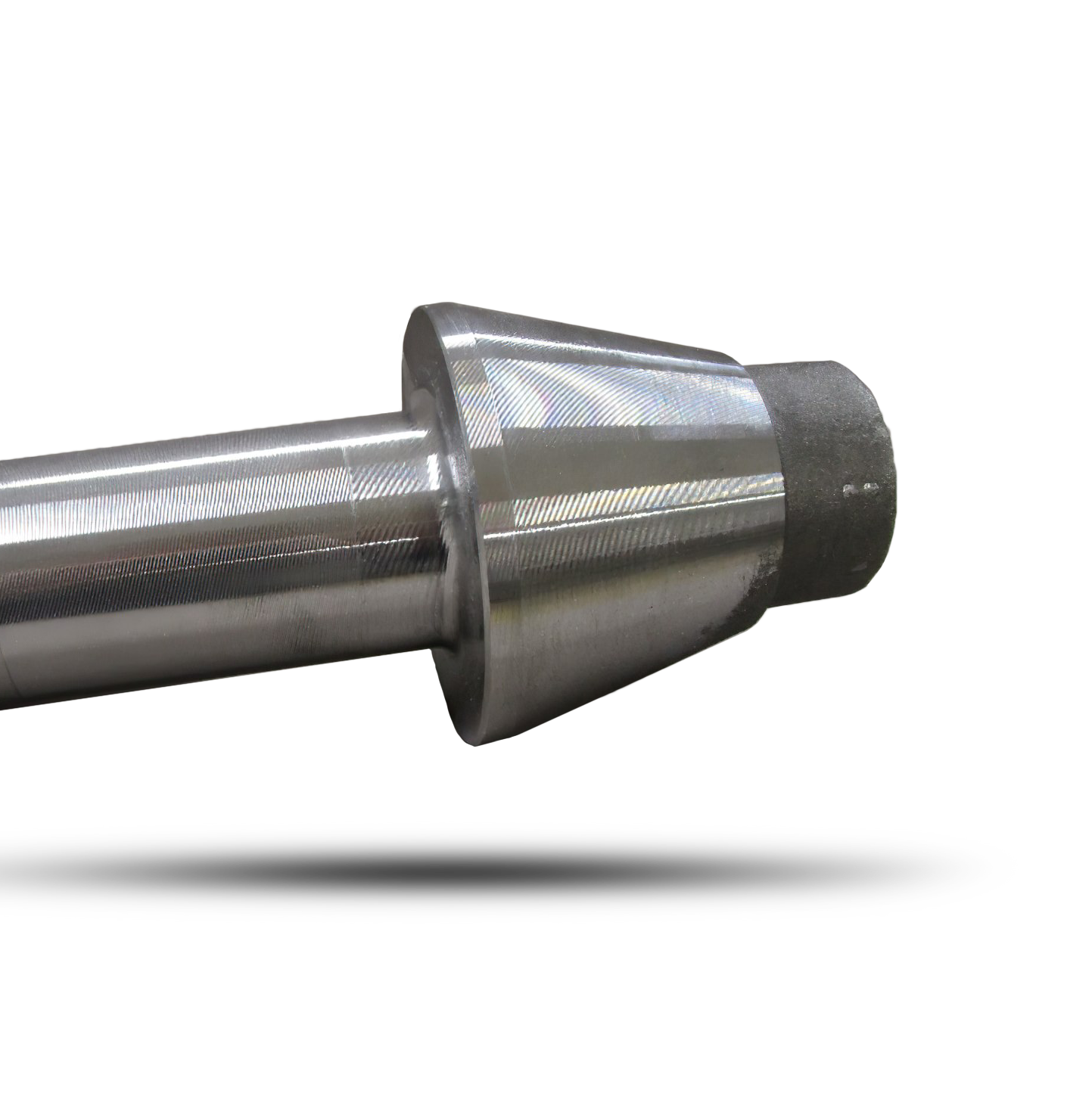

We craft steel parts by means of upsetting, electrical upsetting and hot forging to customer specifications. We carefully follow the production process, from the selection of certified castings to the parts delivery. We execute all stages of production in-house, guaranteeing an efficient, controlled and quality assured service.

Always listening to our customers’ different needs, we look for ways to achieve the best result, exploring new solutions and areas.

Our main goal is to improve every aspect of our business, from reducing production time and waste to workplace wellness, and we pursue this through smooth company organisation and a striving for continuous improvement.

How we workOur passion,

Our passion,

our job,

your satisfaction

We craft steel parts by means of upsetting, electrical upsetting and hot forging to customer specifications. We carefully follow the production process, from the selection of certified castings to the parts delivery. We execute all stages of production in-house, guaranteeing an efficient, controlled and quality assured service.

Always listening to our customers’ different needs, we look for ways to achieve the best result, exploring new solutions and areas.

Our main goal is to improve every aspect of our business, from reducing production time and waste to workplace wellness, and we pursue this through smooth company organisation and a striving for continuous improvement.

ApplicationAreas

Areas

of application

Our many years of experience in steel processing make us a reliable company, able to respond to requests from the most diverse fields of application, from mechanical to energetic engineering, to spare parts and components, without precluding new areas in which to experiment.

Power transmission

36%

Gears

13%

Spare parts

11%

Agriculture

8%

Wind / Solar

5%

Industrial machines

5%

How we workStrong and versatile:

Strong and versatile:

the power of experience

The expertise coming from experience is a guarantee of a delivery service characterised by quality, variety, order

and precision. A service that extends to consulting and the production of parts created

based on specific requirements or needs.

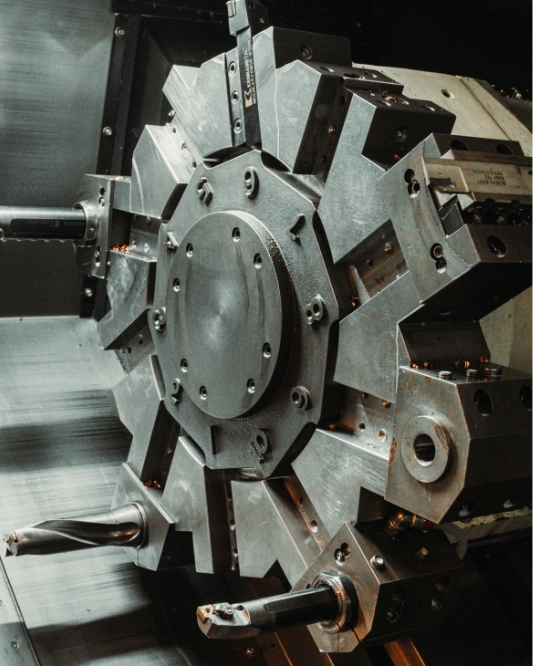

Production processOur technologies,

Our technologies,

Your products

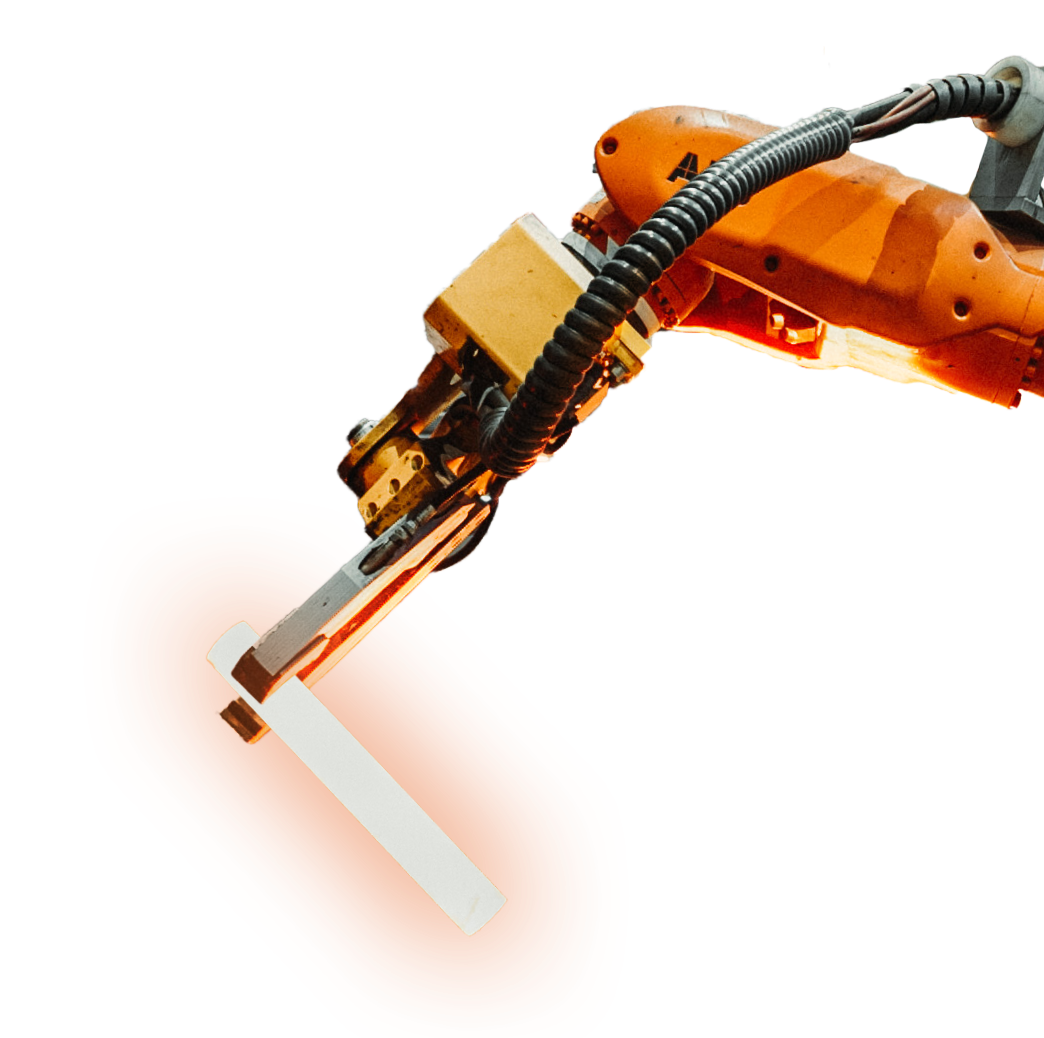

A dedicated team of technicians and skilled workers follows each step of the production process, from the material choice, to the parts delivery, proceeding with accuracy between a functional warehouse, automated production lines and a workshop dedicated to post-production work, always in touch with the customer.

Our methodQuality

Quality

as a method

Our concept of quality is based on the belief that it is not a goal, but rather a method that is applied to every aspect of our operations: from the choice of raw materials, through the production process and the working environment, to the finished product.

Why choose us

Our plus

Know-how, attention to detail and customer focus are the principles that guide our choices and translate into real economical, technical, managerial and qualitative benefits.

There are many reasons to choose us, just as many to stay with us. Find out which ones:

- Careful selection of raw materials

- Capacious and organised internal warehouse

- In-house production of moulds

- High technical preparation of the staff

- Willingness to listening and counselling

- Full attention to reduction of production time and material waste